Electronics Components Manufacturing Scheme (ECMS)

- 31 Oct 2025

In News:

The Government of India has cleared the first batch of seven projects worth ?5,532 crore under the Electronics Components Manufacturing Scheme (ECMS), marking a critical milestone in India’s transition from assembling finished electronic products to building a strong component-level manufacturing base. These approved projects are expected to generate ?36,559 crore in production, create over 5,100 direct jobs, and significantly reduce India’s import dependence in high-value electronic components.

Overview of the ECMS

The Electronics Components Manufacturing Scheme (ECMS) is a flagship initiative under the Ministry of Electronics and Information Technology (MeitY). Approved by the Union Cabinet in 2024, its objective is to strengthen India’s backbone in the electronic components and materials ecosystem.

Key Objectives

- Promote domestic manufacturing of bare components, sub-assemblies, and specialized materials.

- Enhance domestic value addition (DVA) across the electronics supply chain.

- Integrate Indian manufacturers with Global Value Chains (GVCs), especially in semiconductors, telecom, EVs, and renewable energy.

- Support capital investments through a mix of turnover-linked, capex-based, and hybrid incentives.

Tenure and Incentive Structure

- Turnover-linked incentive: 6 years, with a 1-year gestation period.

- Capex incentive: 5-year support window.

Projects Approved Under the First Batch

The first set of projects includes manufacturing units for:

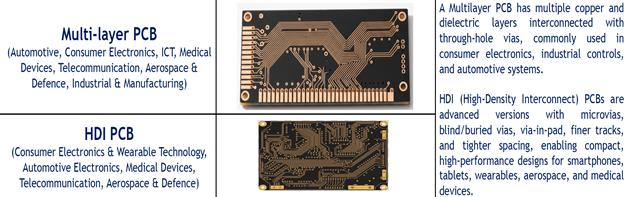

- High-Density Interconnect (HDI) PCBs

- Multi-Layer PCBs

- Copper Clad Laminates (CCL)

- Camera Modules

- Polypropylene Films

These units are spread across Tamil Nadu (5 units), Andhra Pradesh (1 unit), and Madhya Pradesh (1 unit), promoting regional dispersion of advanced electronics manufacturing.

Strategic Impact on Domestic Manufacturing

Meeting Domestic Demand

- New manufacturing units will meet 100% of India’s demand for Copper Clad Laminates.

- 20% of domestic PCB demand and 15% of camera module demand will be met locally.

- Around 60% of total production from these plants is expected to be exported, strengthening India’s global integration.

Camera modules, PCBs, and base materials form the essential components in smartphones, laptops, drones, robotics, medical devices, automotive electronics, and industrial systems — sectors critical for future economic growth.

India’s Strong Entry into Base Material Manufacturing

- A major breakthrough is the establishment of India’s first Copper Clad Laminate manufacturing unit, which serves as the foundational material for multi-layer PCBs. Previously, the entire requirement was imported, exposing India to supply chain vulnerabilities.

- Similarly, Polypropylene Films, vital for capacitor production used in consumer electronics, automotive components, telecommunications, computing equipment, and industrial systems, will now be manufactured domestically.

Economic and Industrial Impact

- Import Reduction: Key components and base materials will be produced domestically, reducing foreign dependency.

- Cost Reduction: Local production will bring down manufacturing costs and improve competitiveness.

- High-Skill Employment: Over 5,100 direct jobs from the first batch and potentially 91,600 jobs across the scheme will be created, according to scheme projections.

- R&D Strengthening: The initiative fosters technology absorption and innovation capability.

These seven approved projects form part of a much larger response — with 249 applications received representing ?1.15 lakh crore investment, potential production of ?10.34 lakh crore, and 1.42 lakh jobs, marking the highest-ever investment commitment in India’s electronics sector.

Integration with National Electronics Vision

ECMS is designed as a complementary pillar to:

- PLI Scheme for Large-Scale Electronics Manufacturing

- India Semiconductor Mission (ISM)

Together, they aim to create a seamless end-to-end manufacturing chain, covering devices, chips, components, materials, capital equipment, and innovation ecosystems.

Electronics Components Manufacturing Scheme (ECMS)

- 10 Apr 2025

In News:

The Ministry of Electronics and Information Technology (MeitY) has notified the Electronics Components Manufacturing Scheme (ECMS) in April 2025. It marks a strategic step in India’s ambition to become a global electronics manufacturing hub.

Key Highlights of ECMS

- Objective: To incentivize domestic production of passive electronic components and capital equipment, thus deepening India's electronics manufacturing value chain.

- Scheme Tenure: Valid for 6 years, with a 1-year gestation period.

- Focus Components: Includes resistors, capacitors, relays, switches, speakers, connectors, inductors, special ceramics, and other passive components.

- Active components are supported separately under the India Semiconductor Mission (ISM).

- Incentive Structure:

- Turnover-linked incentive (based on incremental revenue).

- Capex-linked incentive (for investments in plant and machinery).

- Hybrid model (combining turnover and capex benefits).

Incentive rates range between 1–10%, varying by year and component type.

- Employment Mandate: All applicants—whether component manufacturers or capital equipment makers—must commit to job creation, ensuring broader socio-economic benefits.

Strategic Importance

- Horizontal Sectoral Impact: The scheme is designed to support multiple sectors including automotive, consumer electronics, medical devices, power electronics, and electrical grids, promoting cross-industry multiplier effects.

- Support for Tooling & Capital Equipment Industry: Encourages design and manufacture of capital tools and machinery required for electronics production, in line with models seen under the India Semiconductor Mission.

- Global firms like Linde have begun operations, with more in pipeline.

India’s Electronics Growth Trajectory

- Export Milestone (FY 2024–25):

- Total smartphone exports: ?2 lakh crore

- iPhone exports alone: ?1.5 lakh crore

- Sectoral Growth (Last Decade):

- 5x growth in production.

- 6x growth in exports.

- Export CAGR: >20%

- Production CAGR: >17%

- Manufacturing Base Expansion: Over 400 production units (large and small) now manufacture a wide range of electronic components domestically.

- Value Chain Evolution: India has transitioned from assembling finished goods → sub-assemblies → deep component manufacturing, now entering a value-added, self-reliant phase in electronics